Before choosing the right cable tray for your cabling system and deciding on the features and maintenance and support methods required for it, it is better to consider some considerations.

1- Where is the cable tray supposed to be used?

Installation location and installation considerations:

The position and place where the cable tray is installed affects the size and strength of the cable tray that is to be used:

See the types of cable trays here.

Indoor environments

Industrial installations may require a concentrated load of 200 pounds for which a cable tray is required.

Factors such as the appearance of the cable tray, its weight and the available space are important in installing the cable tray in office environments and should be taken into consideration.

The ambient air also determines the type and material of the cable tray as well as the need for covering and insulation for it.

The use of cable trays in dangerous environments also requires the use of standard and acceptable cable trays.

external environments

Environmental conditions such as electric charge, ice, snow, vibration and shaking are effective on the choice of the type and material of the cable tray. If the environmental conditions are such that there is a possibility of rusting and failure of the cable tray, it is necessary to choose a cable tray and connections that are rustproof and insulated and have more resistance in these environments.

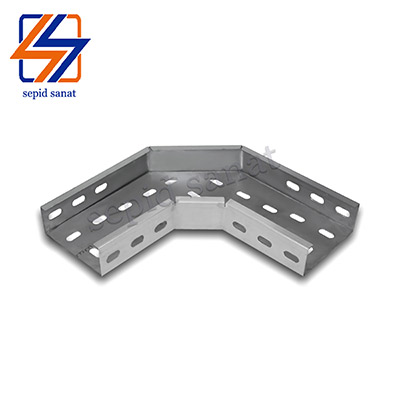

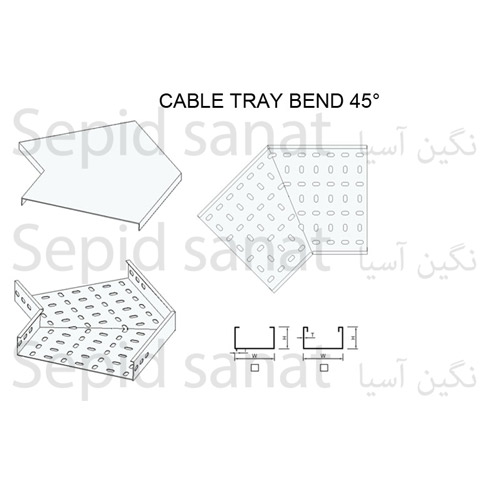

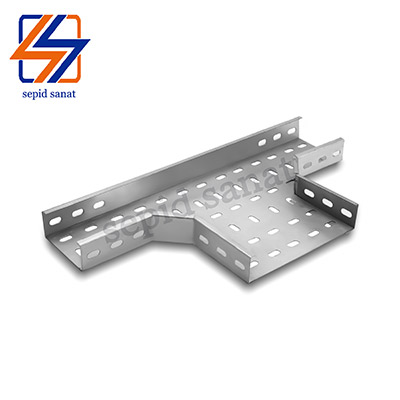

Dangerous external environments also affect the use of the required cable tray and its standards. 2- What kind of cable tray and how many are needed? The NEC specifies the regulations and standards for cable trays in terms of size, height, and depth that are written on them. Support methods and capabilities determine the type of cable tray floor. The largest bending radius of the cable tray determines and controls the radius of other connections. The total weight of the cables used also determines the amount of load required for the cable tray. 3- What are the future needs of your system? The cable tray should be selected and installed in such a way that in the future, if changes are needed, these changes can be easily applied, and the system has the capacity and ability to expand and upgrade.